In our fast-paced, hyper-connected world, smartphones have become inseparable from daily life. These devices fit in the palm of our hand, yet they carry within them a global footprint of mining, manufacturing, logistics, and data consumption. Each new upgrade, each yearly launch cycle, feeds into an increasingly unsustainable chain of resource extraction, carbon emissions, and electronic waste.

This article dives deep into what it truly takes to build, ship, and utilize a smartphone—from the rare earth metals in your circuit board to the server farms powering your cloud backups. We’ll also explore the environmental consequences of these systems and, more importantly, what can be done to mitigate their impacts. By understanding the lifecycle of our devices, we can begin to reframe how we interact with technology—and how we demand better from those who make it.

1. Mining the Modern World: Where Smartphones Begin

Every smartphone starts its life underground. Within each device is a cocktail of more than 60 different elements, including rare earth metals, lithium, cobalt, gold, tin, and tantalum. These materials are not only finite; their extraction is often associated with severe environmental degradation and human rights concerns.

Key Materials and Their Impacts:

- Lithium: Used in rechargeable batteries. Extracting lithium from salt flats in Bolivia, Argentina, and Chile consumes massive amounts of water—up to 2 million liters per ton of lithium.

- Cobalt: Sourced primarily from the Democratic Republic of Congo, cobalt mining has been linked to child labor, toxic dust, and groundwater contamination.

- Rare Earth Elements (REEs): Essential for screen displays and speakers. REE mining often produces radioactive waste and toxic slurry, particularly in unregulated areas of China.

Science-backed stat: According to the European Commission, mining for smartphone components generates about 85–95% of the total environmental impact of a device during its lifecycle.

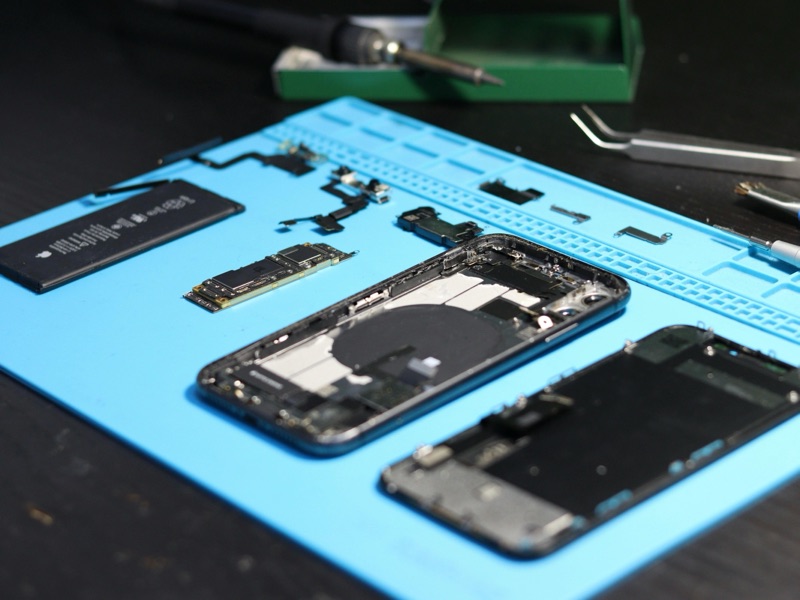

2. The Manufacturing Footprint: Energy, Water, and Waste

Once the raw materials are mined, they’re refined, processed, and assembled into finished components. This often takes place in massive factory complexes in China, Taiwan, Vietnam, and India. The manufacturing stage is energy-intensive and involves high-temperature processes, chemical treatments, and precision engineering.

Environmental Toll:

- Carbon Emissions: The production of one smartphone emits approximately 55–95 kg of CO₂, depending on the model and manufacturer.

- Water Usage: Semiconductor fabrication (used to make smartphone chips) requires ultra-pure water—about 2,000 gallons per smartphone on average.

- Toxic Byproducts: Manufacturing semiconductors and screens involves arsenic, hydrofluoric acid, and solvents that are difficult to dispose of safely.

Additionally, factory workers in the electronics supply chain are frequently exposed to hazardous chemicals without adequate protection, leading to long-term health effects.

3. Global Shipping and Logistics: The Carbon Trail

From factory floors to store shelves, smartphones are shipped across continents, sometimes crossing the globe several times during assembly. Components are often sourced from multiple countries and assembled in a final location for shipment.

- Air freight and maritime shipping burn fossil fuels, contributing to global CO₂ emissions.

- Packaging, although improving in some cases (e.g., Apple removing chargers), still contributes to an estimated 1–2 kg of CO₂ per device.

According to the International Transport Forum, global freight contributes to around 8% of global greenhouse gas emissions, and electronics are a significant share of that freight.

4. The Operational Phase: Cloud Data and Energy Use

Once the phone is in your hands, the environmental impact doesn’t end. Although smartphones themselves are relatively energy-efficient, their usage is tied to massive infrastructure—cell towers, internet backbones, and cloud data centers.

Ongoing Impacts:

- Data Consumption: Streaming video, using AI apps, and storing photos in the cloud all require constant data processing. The average smartphone user generates 60–100 GB of data traffic per month, much of it supported by energy-hungry server farms.

- Data Centers: Google and Amazon’s cloud services operate hundreds of data centers globally. These consume an estimated 200 terawatt-hours of electricity annually—roughly the same as South Korea’s total power use.

- Battery Charging: While small in isolation, charging billions of phones daily adds up to 34 terawatt-hours per year, equivalent to the electricity used by 3 million U.S. homes.

5. The End of the Line: E-Waste and Disposal

Smartphones have notoriously short life cycles. Most users upgrade every 2–3 years, driven by marketing cycles, planned obsolescence, or performance degradation.

The Waste Problem:

- E-Waste Volume: In 2023, the world generated 62 million metric tons of e-waste. Only 17.4% of it was properly recycled, according to the Global E-waste Monitor.

- Toxic Elements: Old phones contain lead, mercury, and cadmium. When dumped in landfills, these can leach into soil and water supplies, creating long-term environmental and health hazards.

- Low Recovery Rates: Even when recycled, recovery of rare earths and precious metals is inefficient—only about 30% of the gold and cobalt can typically be retrieved.

6. What Can Be Done: Industry, Policy, and Consumer Solutions

Despite these bleak statistics, meaningful change is possible. It requires collaboration across manufacturers, policymakers, and consumers.

Solutions on the Horizon:

a. Design for Longevity

- Modular phones (like Fairphone) make repairs and upgrades easier.

- Longer software support (e.g., Apple’s 6–7 years of iOS updates) reduces forced upgrades.

b. Right to Repair Legislation

- The EU and several U.S. states are pushing for laws that ensure parts, tools, and manuals are available to consumers and third-party repair shops.

c. Closed-loop Recycling

- Apple’s “Daisy” robot can disassemble iPhones and recover 14 different materials.

- Companies are researching ways to design phones that are easier to disassemble and recycle.

d. Sustainable Materials and Green Manufacturing

- Companies like Samsung and Fairphone are experimenting with recycled plastics, low-carbon aluminum, and bio-based polymers.

- Transitioning factories to renewable energy (e.g., solar-powered assembly plants) can significantly reduce emissions.

e. Consumer Behavior

- Extend phone lifespan by 1–2 years.

- Buy refurbished devices when possible.

- Use eco-conscious apps and dark mode to reduce energy usage.

- Recycle responsibly through certified e-waste programs (e.g., R2 or e-Stewards standards).

Conclusion: Rethinking Convenience in the Age of Crisis

Smartphones are marvels of human engineering. But their convenience comes at an extraordinary environmental cost—one that is often invisible to the average user. The sleek, pocket-sized design masks a vast web of mining, manufacturing, logistics, and cloud infrastructure that spans the globe and leaves a heavy carbon footprint in its wake.

The good news is this: we can change the trajectory. Through smarter design, better legislation, and informed consumer choices, we can slow down the extractive cycle that underpins modern tech. We can demand devices that last longer, are easier to repair, and respect both people and planet. Because the most powerful upgrade we can make isn’t to the phone in our hands—but to the system that makes it.

Comments

Post a Comment